What is a Kaizen Event?

In fast-paced and resource-constrained environments, teams don’t always have time for long, drawn-out improvement projects. That’s where Kaizen Events come in.

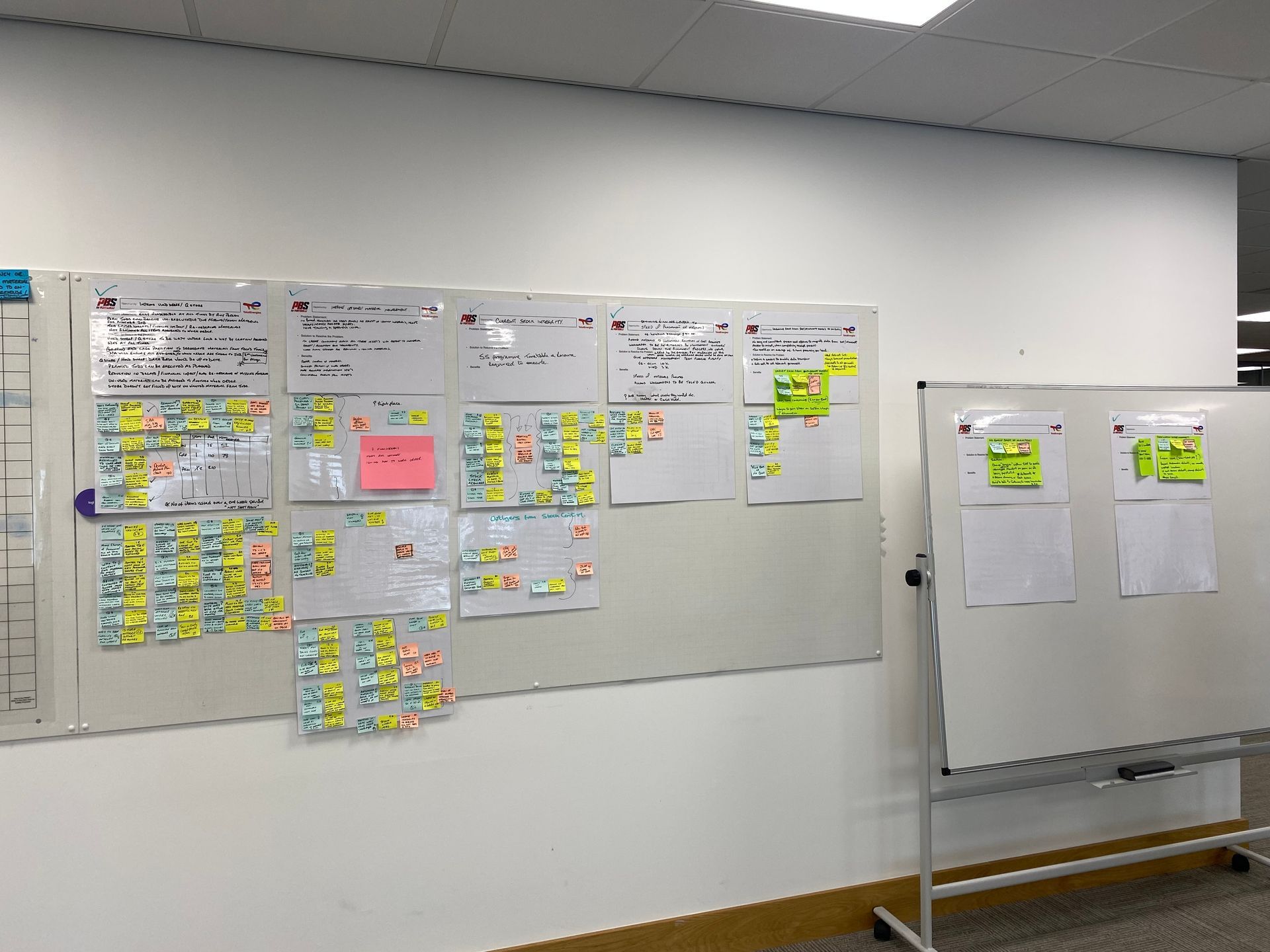

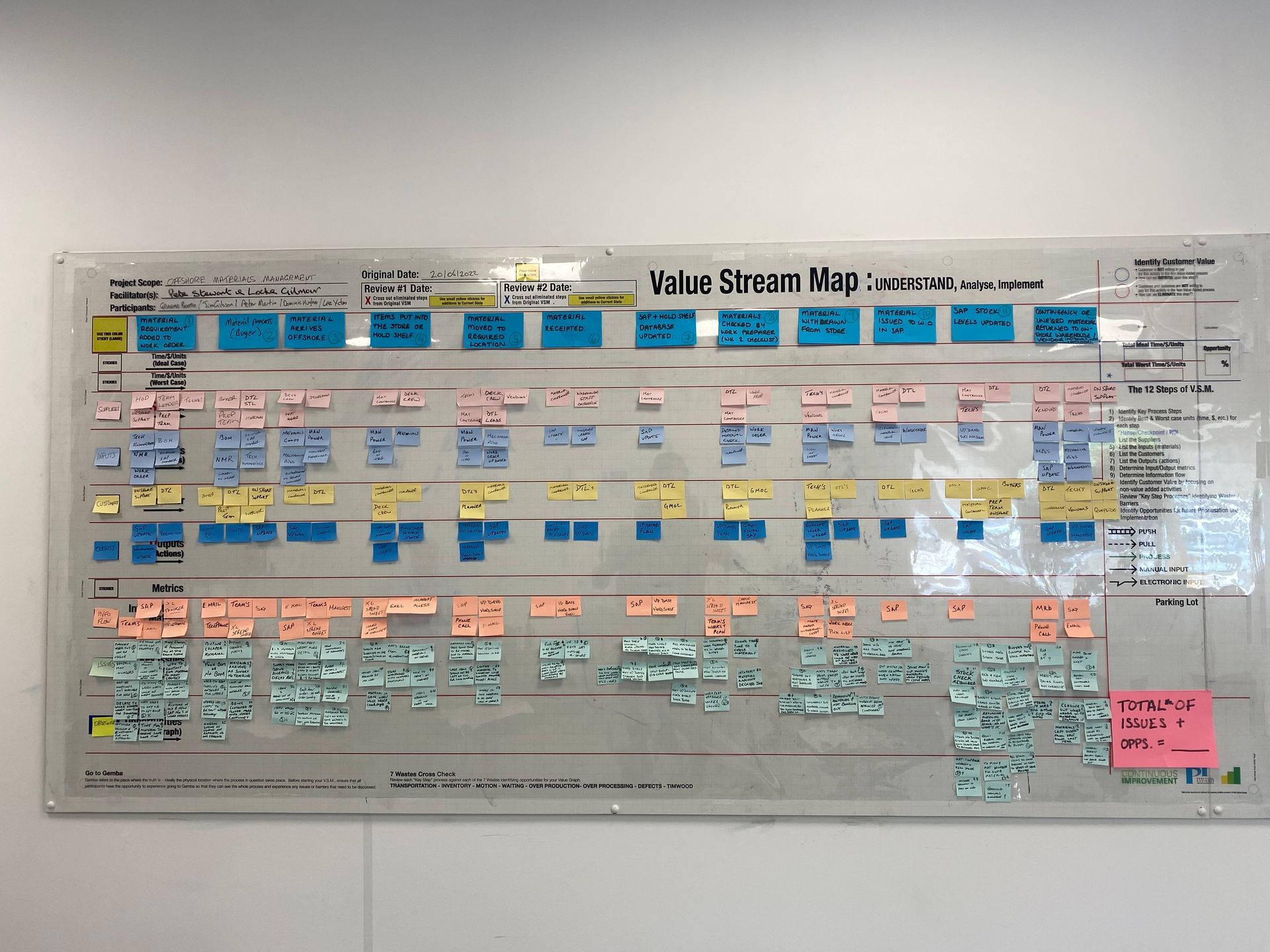

Kaizen Events are short, high-impact improvement sprints that help teams solve targeted problems in just 3–5 days. Grounded in Lean principles, they bring cross-functional teams together to rapidly reduce waste and improve performance across quality, cost, delivery, flexibility, and speed.

But they’re not just about “quick fixes.” Kaizen Events create real, sustainable results by empowering frontline teams to take ownership of their processes, test “do-now” solutions, and implement changes right away.

The Power of a Well-Run Kaizen

A successful Kaizen Event isn’t just a brainstorming session—it’s a disciplined, results-focused workshop that delivers measurable outcomes. By the end of a typical Kaizen, teams are not only running new processes but have built new habits that stick.

In one project with an energy sector client, a multidisciplinary team tackled inefficiencies in their accounts payable process. Over just 3 days, they prioritised 78 actions, addressed late payments and coding errors, and delivered over $115,000 in cost avoidance through time and shipment savings. These are the kinds of outcomes that highlight the real value of Kaizen when it’s well scoped and well supported.

What Makes Kaizen Events Work?

- Focus: Kaizen Events target specific, well-defined problems—whether that’s a recurring defect, a slow turnaround time, or a process bottleneck.

- Speed: With dedicated time and committed resources, teams move from analysis to implementation in days, not months.

- Engagement: Everyone involved in the process is part of the solution. That means no observers—just active contributors.

- Ownership: Teams walk away with a sense of pride and responsibility for the changes they’ve made.

- Follow-through: A structured follow-up plan (typically 21 days) ensures that actions don’t fall by the wayside.

When Should You Run a Kaizen Event?

Kaizen is ideal when:

- The problem is narrow in scope and clearly defined

- You need results immediately

- There’s an opportunity to break momentum or resistance

- A process is stuck and needs a fresh perspective

- You can dedicate a small team for a few focused days

It’s also an excellent launchpad for larger improvement programmes, giving early wins and building credibility across the business.

In Part 2, we’ll explore when to use a Kaizen Event vs. other improvement approaches, and what makes the timing right.

If you’re ready to build internal Kaizen capability in your business, we’d be happy to share what’s worked for our clients across energy, manufacturing and professional services.